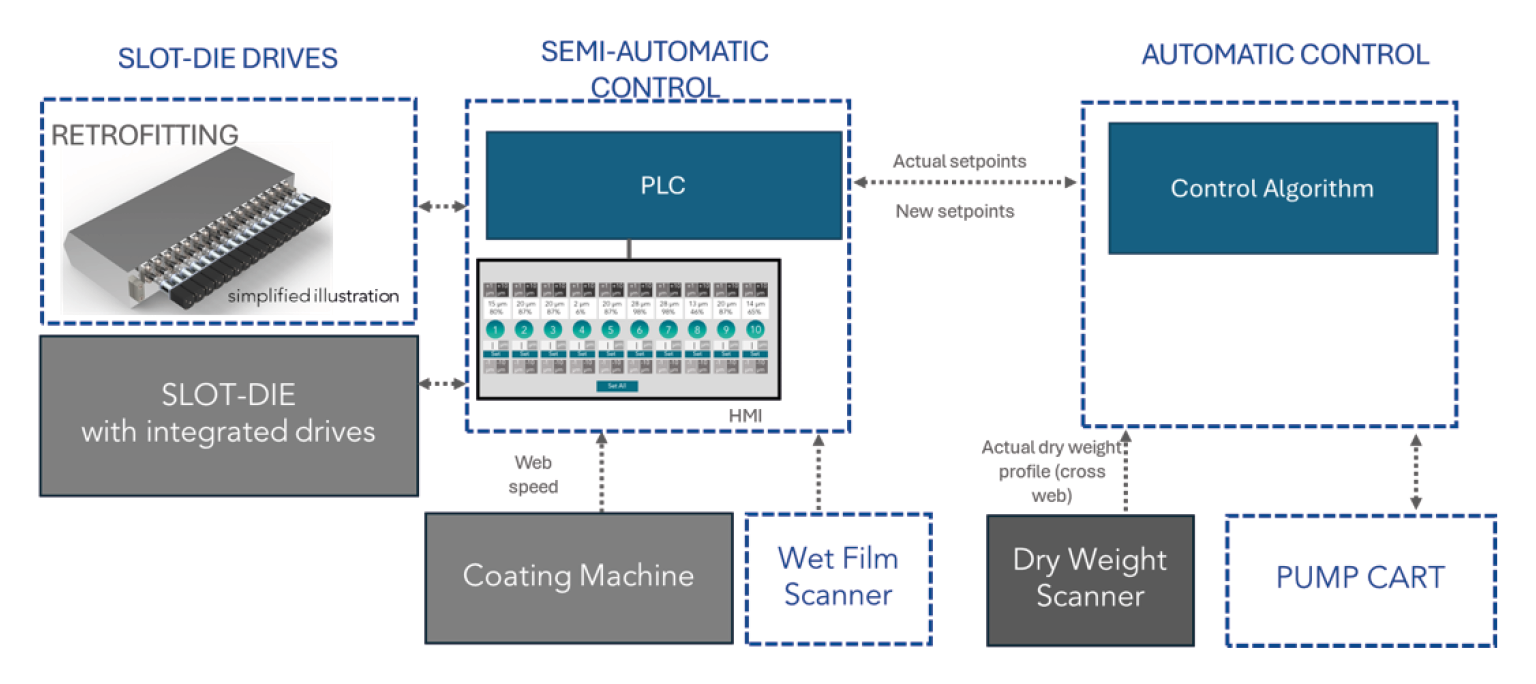

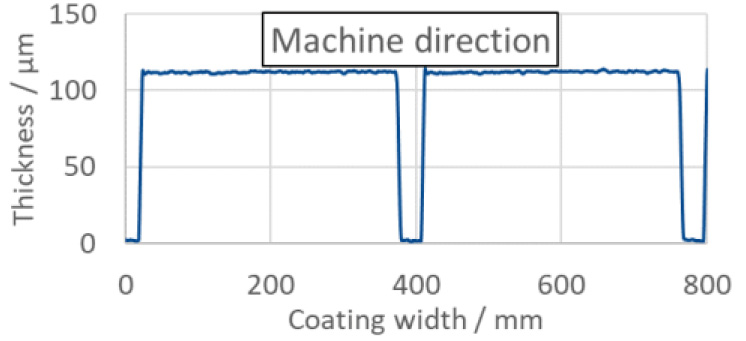

• Automatic control system

• Closed-loop control of length and quality parameters

• Integrated pressure monitoring and control

• Simultaneous coating of different layers / liquids

• Inline logging of KPIs

• Easy integration into existing lines

• Easy to clean

• Upgradeable for higher coating speed up to 85 m/min

| Performance | |

|---|---|

| Length of coating / non-coating | ≤ 5 mm - ∞ (≤ 1 mm depending on condition) |

| Patch Format | Up to 5 different coating / non coating length per sequence |

| Speed range | 1 m/min – 30 m/min |

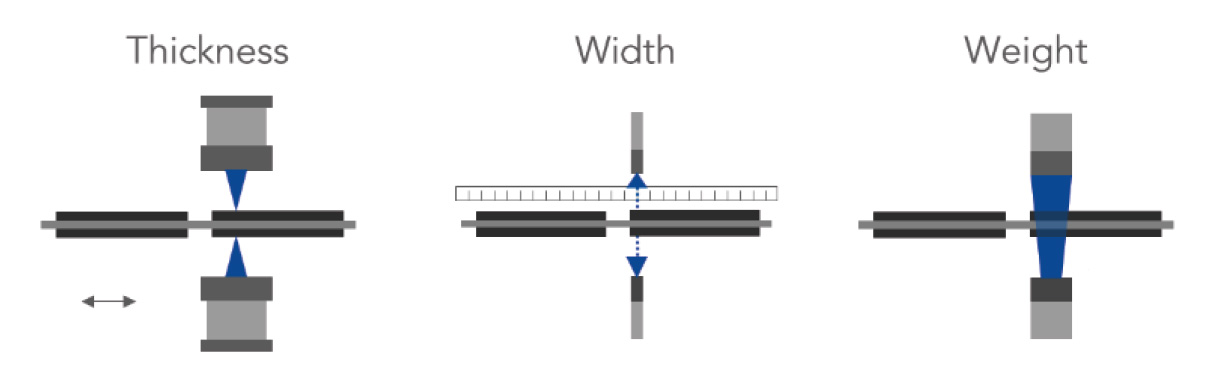

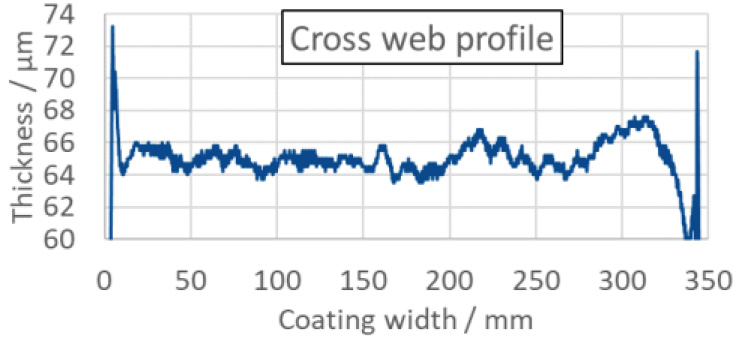

• Measuring all important values in one combined scanner

• Multi-sensor: Up to 3 in 1 (Thickness, Width and Weight)

• Small installation space (Customizable for retrofitting)

• Closed-loop control of coating

| Performance | |

|---|---|

| Thickness sensor Resolution | < 1 μm |

| Thickness spot size | 10 μm |

| Width sensor | Width, position and offset of coating stripes / non-coating and foil |

| Width Resolution | < 0.1 mm |

| Speed range | 1 m/min – 150 m/min |

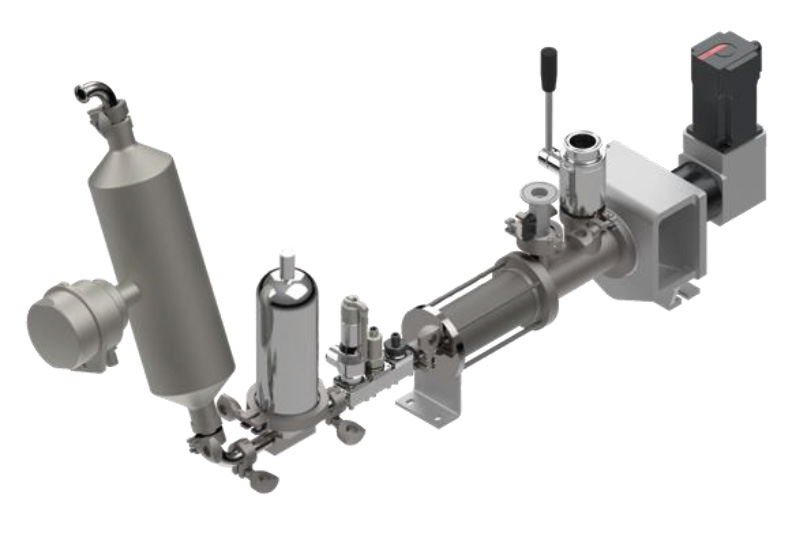

• Closed-loop control of coating weight

• Pulsation-free, precise dosing

• Lean design / low hold-up volume

• Integrated sensors for pressure and temperature

• Option for flow meter and viscosity meter

• Excellent reachability of components

• Easy to setup and to clean

• Made for simultaneous multilayer-coating

| Performance | |

|---|---|

| Volume flow | 100 ml/min up to 15.000 ml/min |

| Speed range | 1 m/min – 150 m/min |

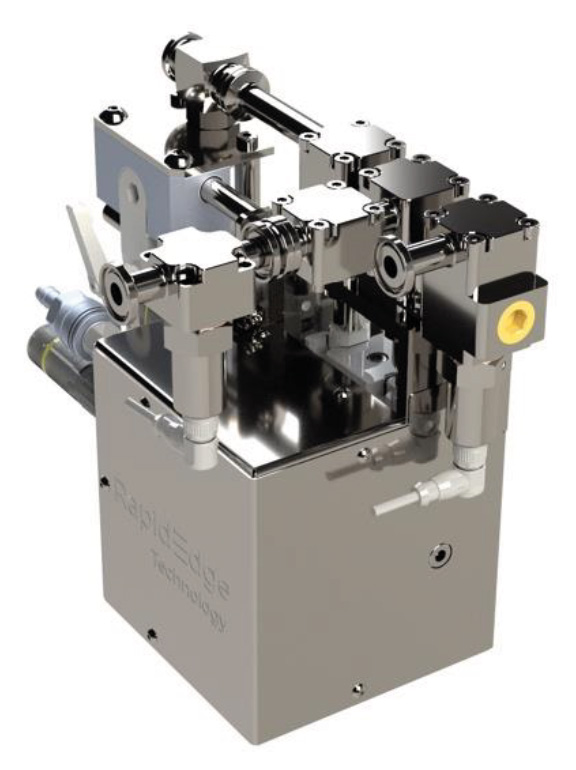

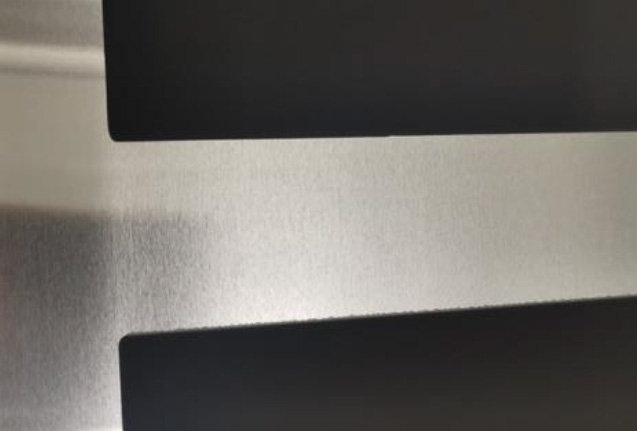

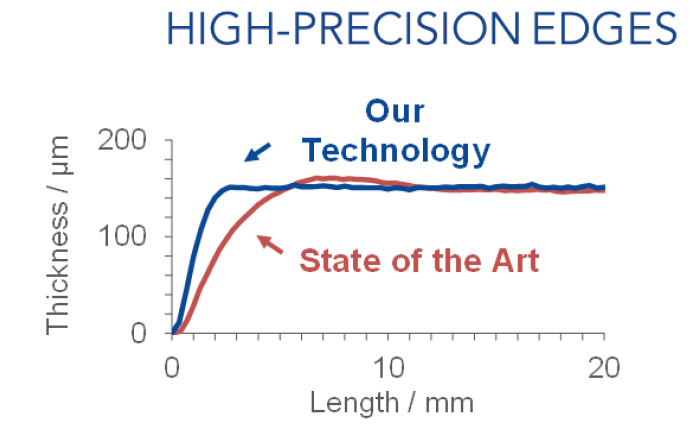

• Automatic adjustments of flexible slot-die

• Faster start-up of coating

• Saving / restoring the last settings

• Retrofitting: RapidEdge drives for existing slot-dies

• Reproducible adjustment via HMI, no manual bolt

adjustment

• Automatic adjustment with feedback loop

| Performance | |

|---|---|

| Speed range | 1 m/min – 150 m/min |